Pneumatic Valve -Plus

Factories around the world that have the ability to design and manufacture large size pinch valve is very few, for example: Red Valve, FLOWROX, Jindex, and etc.

As the “core part” of pinch valve, the rubber valve sleeve has high requirements on the manufacturing capability of the suppliers with the size increase of pinch valve. It requires not only large-scale rubber processing and vulcanization equipment, but also a mature and reliable manufacturing process of valve sleeve, which is the basis for manufacturing large-size pinch valves.

FENGCHI have these basic conditions to design and manufacture DN600-DN2000 large-size pinch valves maturely.

- Technical Parameter

- Advantage Characteristics

- Downloads

Size range:

15~2000mm, ½~84in

Pressure range:

1-10MPa, 1:2 safety factor, which means bursting pressure is 2 times higher than the operating pressure.

Material of valve body:

DN15~200 (carbon steel, ductile iron, aluminum alloy, stainless steel-casting process);

DN250~2000 (45#steel, stainless steel welding technology );

Material of valve sleeve:

NR, EPDM, CR(chloroprene rubber), NBR, butyl rubber, FPM, Hypalon rubber.

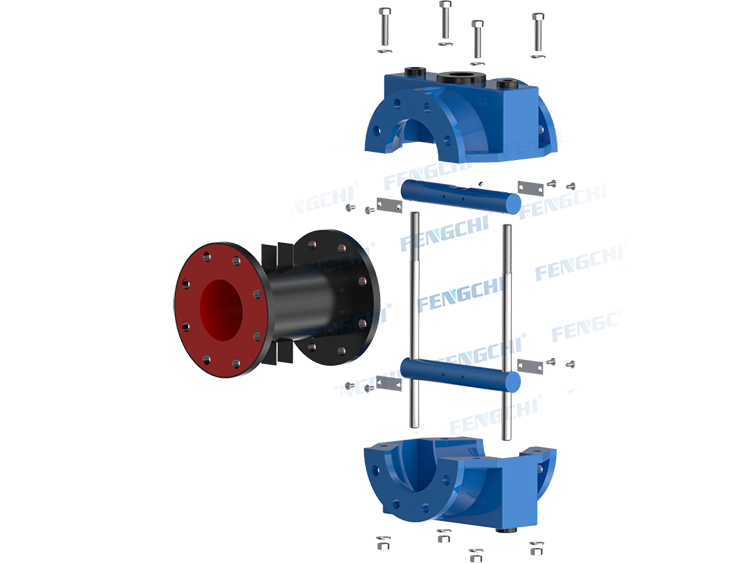

Explosion diagrams of components:

Full bore - no flow restrictions.

Shut off on the center line - extend the service lifetime of valve sleeve.

Valve sleeve is the only part in contact with the medium-the only wearing part.

Self-cleaning - no clogging.

Wide variety of material for valve sleeve-to fulfill the requests of fluid medium.

Strong construction design of metal valve body - extend service intervals.

Core of pinch valve is the rubber sleeve, which is the only part in contact with the process medium.

Customized design of valve sleeve according to customer's process conditions, prefer the optimal valve sleeve.

Basic type, extra thick type, high pressure type, Conical type, negative pressure resistant type,Reduced diameter

When service lifetime of pinch valve comes to end, it will become an almost new pinch valve after the valve sleeve is replaced.

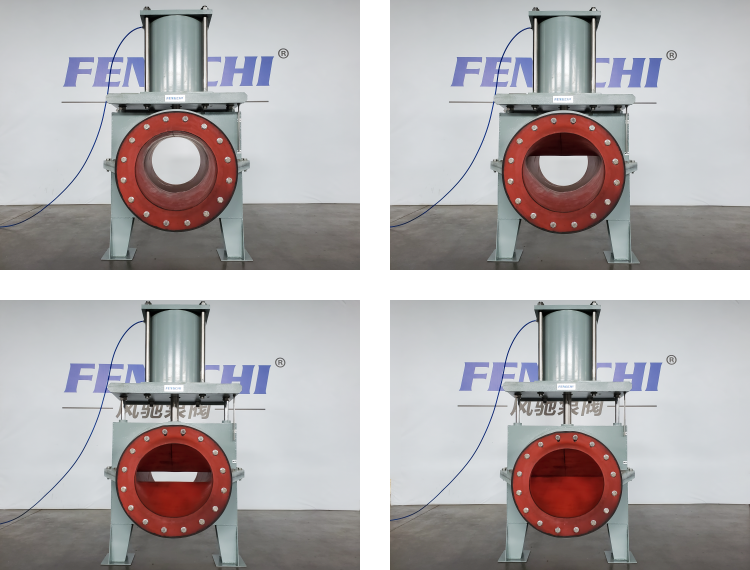

Working status of pinch valve:

Fully-open: the full-bore elastic valve sleeve of pinch valve without any gaps & dead spots.

Center closed: closed on the center line of the valve body, which avoids turbulence and abrasion, as a result, the valve sleeve becomes a smooth and enclosed venturi with self-cleaning during every operation.

Fully-closed: it ensures the pinch valve is with no leakage of two ways when shut off, and the safe design of inner valve sleeve requires no maintenance of sealing elements.