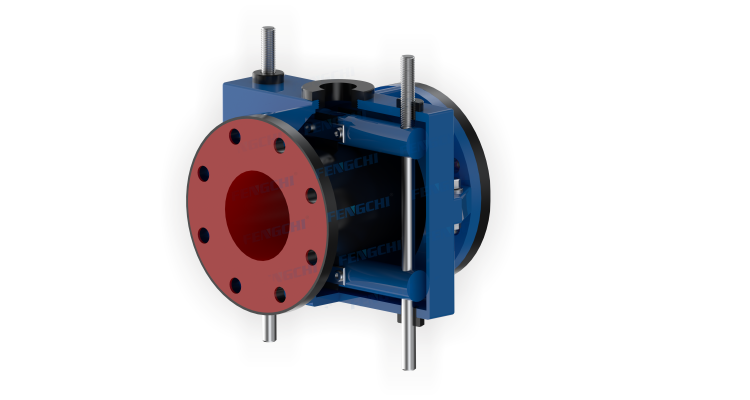

High Pressure Type

Constructions applicable to various kinds of process conditions

High pressure sleeves are designed for high pressure applications. The high pressure sleeve features stronger fabric reinforcement and thicker construction compared to a standard one. The mating flanges are equipped with integrated O-ring seals to ensure a tight seal under high pressure applications.

- Technical Parameter

- Advantage Characteristics

- Downloads

Size range:

15~2000mm 1/2~80in

Pressure grade:

1~10Mpa 1:2 safety factor, which means bursting pressure is 2 times higher than the operating pressure.

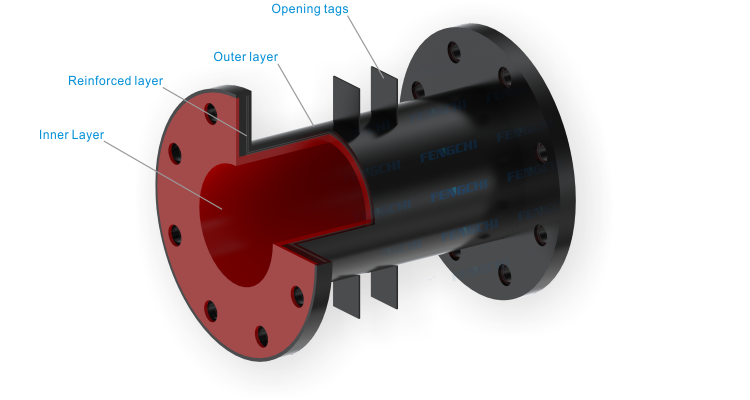

Analysis of construction:

Inner Layer: adopt various kinds of rubber materials or formulas in order to fit for the high demanding applications involving abrasion, corrosion or high temperature, etc.

Reinforced layer: the perfect combination of synthetic rubber and synthetic fibre technology forms a unique reinforced skeleton, which enables the sleeve to bear pressure and fatigue.

Outer layer: Using Natural Rubber to protect and reinforce the flexure resistance of valve sleeve.

Opening tags: the middle part of the outer layer is equipped with opening tags to solve the problem of fixation and tensile strength of the inner sleeve and actuator, also to ensure full opening of valves in all process conditions.

Handmade:

Each FENGCHI pinch valve sleeve is handcrafted by professionally trained personnel, each sleeve is affixed with labels, which contains relevant parameters and numbers in order to provide a basis for quality traceability.

Material, features and matching process conditions

Material | Working Condition | Proper Temperature | Applicable Media |

| SBRT | Severe wear high-frequency operation | -40~+110℃ | Abrasive material, weak acid, weak base and other chemical media |

| EPDM | Chemical applications/Applicable to 75% of all industrial chemical applications | -40~+120℃ | Concentrated and oxidizing chemicals |

| NR | Strong abrasive and corrosive conditions | -40~+75℃ | Abrasive materials.Weak acid, weak base and other chemical media |

| NRF | foodstuff applications | -40~+75℃ | Media used in food and other alcohol used in CIP (clean-in-place) processes. |

| NRL | Strong abrasive and corrosive conditions (including slurries ) | -40~+75℃ | Abrasive pulp such as ore pulp.Weak acid, weak base and other chemical media |

| NBR | suitable for oil and aliphatic hydrocarbons | -30~+100℃ | Oil, fat, fuels, Hydrocarbons Lubricants, etc. |

| NBRF | Applications of fatty foodstuff, compliant with FDA (Food & Drug Administration ) requirements | -30~+100℃ | Vegetable and animal oils and fats |

| HNBR | high temperature applications | -30~+160℃ | Oils, fats, fuels, Hydrocarbons, Lubricants, etc. |

| CR | Applications of special-purpose chemicals. Resistance to Ozone and bad weather. | -30~+100℃ | Chemicals, acids, several solvents, fatty oils, greases, lubricants. |

| FKM | Applications of special-purpose chemicals. Resistance to Ozone and bad weather. | -20~+120℃ | Chemicals, fatty oils, aromatic and halogenated hydrocarbon. |

| CSM | Applications of special-purpose chemicals. Resistance to Ozone and bad weather. | -40~+100℃ | Chemicals, acids, several solvents, fatty oils, greases, lubricants. |

| IIR | Applications of special-purpose chemicals. Impermeable to gas | -40~+100℃ | Concentrates and Acidic Chemicals. Vegetable oils. |

| PU | Process conditions of abrasive mediums | -10~80℃ | Abrasive materials, dilute chemicals, hydrocarbon oils, lubricating oils. |

FENGCHI pinch valve is designed specially for low maintenance, there are no seats, packing, sealing ring, or expansion pipes to replace. Valve sleeve is the only replacement needed in pinch valve. It will become an almost new pinch valve after the sleeve is replaced. FENGCHI® pinch valve barely needs inventory for other components.